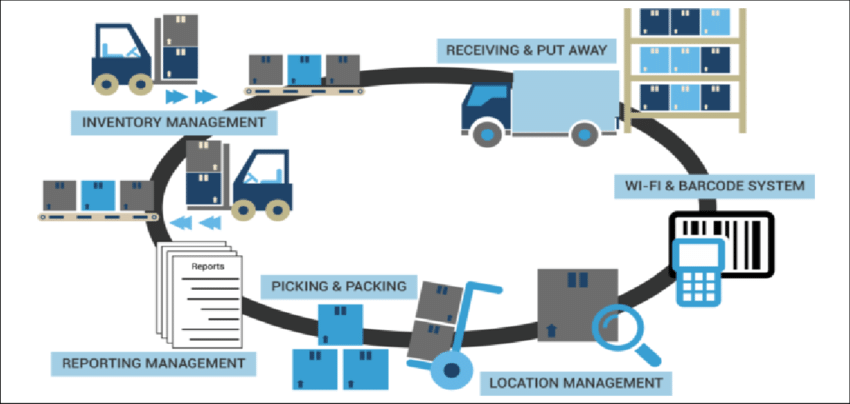

Product reception, putaway, and storage are all aided by the warehouse management system – WMS.

Supply chain solutions provider MVP uses WMS to run its 500,000 square feet of warehouse space, which serves around 40 clients, “efficiently and precisely,” according to Dirk Updike, vice president, operations.

When it’s time to collect products, the system instructs warehouse workers to use hand-held devices to navigate the most efficient routes to the appropriate spots. When compared to a typical, non-RFID environment, the WMS boosts warehouse efficiency by around 40%, according to Updike.

Information has become increasingly important to good supply chain management as supply chains become more complicated and delivery time frames shorten. WMS solutions are becoming more important as a result of this. Companies may benefit from a strong WMS by leveraging data and operating more effectively.

In this article, we’ll go through 13 steps for a successful warehouse management system – WMS deployment:

1. WHEN DO YOU REQUIRE A WMS?

The requirement for a WMS can be influenced by the size of the business; larger operations are more likely to benefit from one. According to Dan Gilmore, chief marketing officer at Softeon, a supply chain solutions provider, warehouse complexity, which is generally caused by the types of units handled and the amount of operations, is most commonly what drives the decision.

The “eaches” picking, which is common in e-commerce sales, is more complicated than pallet operations. Similarly, having a variety of product types—for example, a mix of those that require refrigeration or freezing—increases complexity..

If expanding warehouse staff is the only option to regularly meet service needs, Boykin believes it’s time to think about a WMS.

Assess whether you can handle the challenges more cost-effectively by using underused functionality in existing systems or through third-party addons before investing in a WMS, suggests Tom Singer, principal of Tompkins International, a supply chain consulting business.

2. A WMS CAN SUPPLY A VARIETY OF CAPABILITIES.

“A warehouse management system (WMS) has the power to streamline day-to-day warehouse operations and deliver greater efficiency to maximize customer satisfaction,” says Allyson Griffin, Oracle industry principal. A WMS can reduce stockouts and improve customer service by offering real-time visibility into inventory.

It can also improve pick pathways, resulting in higher inventory turns and lower inventory carrying costs. Inbound, putaway, and picking, among other activities, can be streamlined with robust logic within a WMS.

By decreasing paper-based activities and implementing system-directed tasking, a WMS can boost efficiency by assigning personnel based on the three Ps: permission, priority, and proximity. If a pallet needs to be moved from storage to picking, the WMS can assess the job’s priority, determine which workers are capable of moving it, and locate those who are closest to the pallet. This intelligence color is red.

At the same time, attempting to take advantage of all of a WMS’s features might become a cumbersome, never-ending endeavor. Focusing on the functions that will improve individual warehouse operations is often more effective. “It’s not a hundred things; it’s eight to twelve,” Gilmore explains.

3. LET BUSINESS LEAD THE PROJECT TO GAIN ADVANTAGE OF WMS

Business units, rather than IT, tend to lead successful WMS implementations. The business divisions should collaborate to identify how the system should function for them and what influence it will have on their operations.

4. EVALUATE YOUR SPENDING POWER FOR WMS

“Any company looking to enter the WMS industry should know which end of the pool to swim in,” Singer says. Finding the ideal WMS vendor and solution necessitates a significant amount of time and effort.

Tier 3 solutions are mostly used to track and confirm what was received, picked, and dispatched. Many Tier 2 systems, which are one rung higher, can provide directed work for receiving, putaway, and restocking, as well as some task optimization. Many provide consumer interfaces and reporting features. Some functions, however, may be restricted.

Tier 1 solutions stand out because of their “depth and quality,” according to Troianello. They offer more advanced controls over order flows, labor allocations, and forecasting capabilities, as well as fast reaction times across all transaction volumes. On the other hand, licensing and implementing them is usually costly.

5. EVALUATE THE REPORTING CAPABILITIES

“The key value of reporting is being able to observe what’s going on on the warehouse floor as it happens,” Singer explains. Best-in-class reporting should, as a result, provide a command and control picture of warehouse activities, allowing problems to be discovered and rectified rapidly. Drilling down into specifics and identifying actions to address difficulties should be possible with the solution.

6. ASK ABOUT “TIME TO VALUE.”

Before seeing a return on investment, firms usually need some time to ramp up and reap productivity benefits after installing a WMS. This can last anywhere from a month to a year—or even longer. “Ask how fast the time to value was while checking references,” Gilmore says.

7. CHECK OUT SOLUTIONS FOR BUSINESS INTELLIGENCE

Business intelligence (BI) can aid a company’s forward and backward planning. According to Jon Kuerschner, vice president of supply chain consultancy at Körber Supply Chain, “BI continues to be vital for looking in the rearview mirror to enhance tomorrow.” The data can be used by management to spot trends, do period-over-period evaluations, and determine next steps.

Forecasting future movements, such as seasonal stock swings, requires business intelligence. “As the volume of data from an organization grows, it becomes more important,” explains Jarrett Leesch, Körber’s senior vice president of international business development and sales.

8. VERIFY CONNECTION OUTSIDE OF THE WAREHOUSE WALLS

WMS is becoming increasingly important as it connects to other supply chain links. Is it possible, for example, for a WMS to incorporate consumer input on sales in order for the warehouse to change its distribution schedule? Boykin says, “We’re going to connect warehouses and distribution centers across the supply chain.”

9. CONSIDER THE VENDOR’S INDUSTRY EXPERIENCE

While a lack of industry experience may not be a deal breaker, it can give you a leg up. “Proven vendor industry experience aids in ensuring that the functionality required is available without the requirement for specific modifications,” Singer explains. Furthermore, a vendor’s success in a particular area frequently leads to the development of additional features for that vertical.

10. EVALUATE THE PROCESS OF UPGRADE

While WMS can improve warehouse operations nearly immediately, the true value is realized over time when firms adjust their processes. This necessitates a well-defined upgrading path. “Every WMS has an upgrade path,” Troianello says, but “they’re sometimes so onerous that enterprises don’t bother doing it.” Examine the upgrade path before deciding on a solution.

11. EVALUATE THE COMMITMENT OF THE PROVIDER

A successful implementation is often dependent on the relationship with the provider, in addition to sturdy, trustworthy technology. Reichert recommends evaluating a number of factors, including the company’s responsiveness and engagement, as well as if it’s interested in finding the best solution, even if it means selling less of its own products.

12. TRAIN AND ADJUST THE DEADLINE

The importance of thorough training cannot be overstated. When an issue emerges, users who don’t completely understand how the WMS works are more likely to revert to their previous ways of processing. Also, if you want to get it properly, don’t be scared to push out an implementation date.

13. CONTINUOUSLY IMPROVE

To get the most out of a WMS, form a continuous improvement team that can identify and implement new ways to use the system’s functionality. After all, once you’ve made the investment in a WMS, it only makes sense to get the most out of it.

Source: inboundlogistics.com

———————————————————————————————————-

Contact us for more information:

Head Office: 01. Hoang Ngoc Phach, Dong Da District , Hanoi city

Email: contact@worldcourier.vn

Facebook: https://www.facebook.com/worldcouriervietnam

Website: https://worldcourier.vn/en/